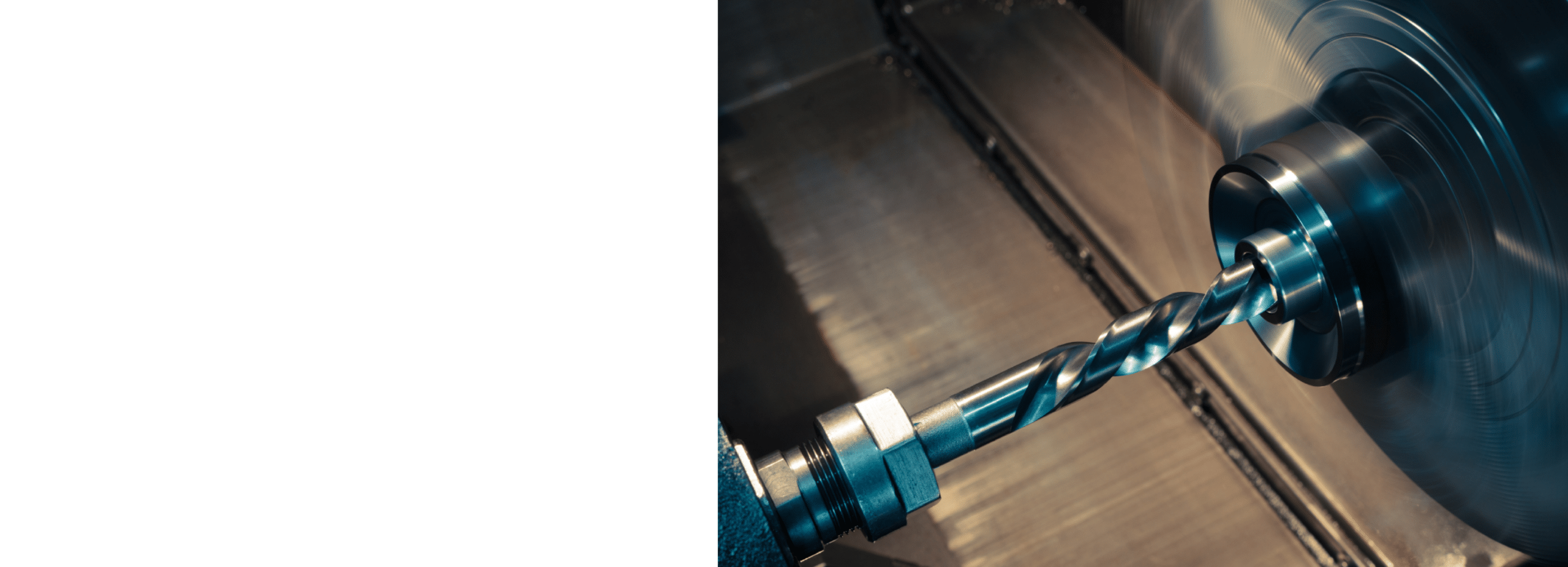

CNC Turning

CNC turning is a widely adopted technique in the manufacturing industry, known for producing high-quality parts with tight tolerances and impeccable surface finishes. By utilizing a CNC lathe, a rotating workpiece undergoes precise machining as a cutting tool meticulously shapes it into the desired form. This enables the creation of cylindrical parts with exceptional accuracy and consistency making it the preferred method for various industrial applications.

What is CNC Turning?

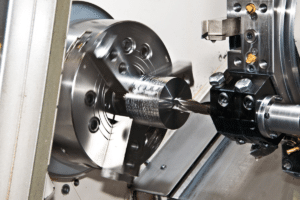

CNC turning is a highly efficient manufacturing process. It involves rotating a solid rod or bar of material, also known as a workpiece, while a cutting tool moves along the length of the part. This precise action effectively removes material from the workpiece, allowing for the production of precision cylindrical parts.

To initiate the CNC turning process, a CAD (computer-aided design) model is first loaded into the CNC (Computer Numerical Control) lathe. The lathe utilizes a fixed cutting tool to accurately remove material from the workpiece based on the specifications outlined in the CAD model. CNC turning is well-regarded for its ability to create intricately designed parts with exceptional accuracy, making it a preferred method for a wide range of industrial applications.

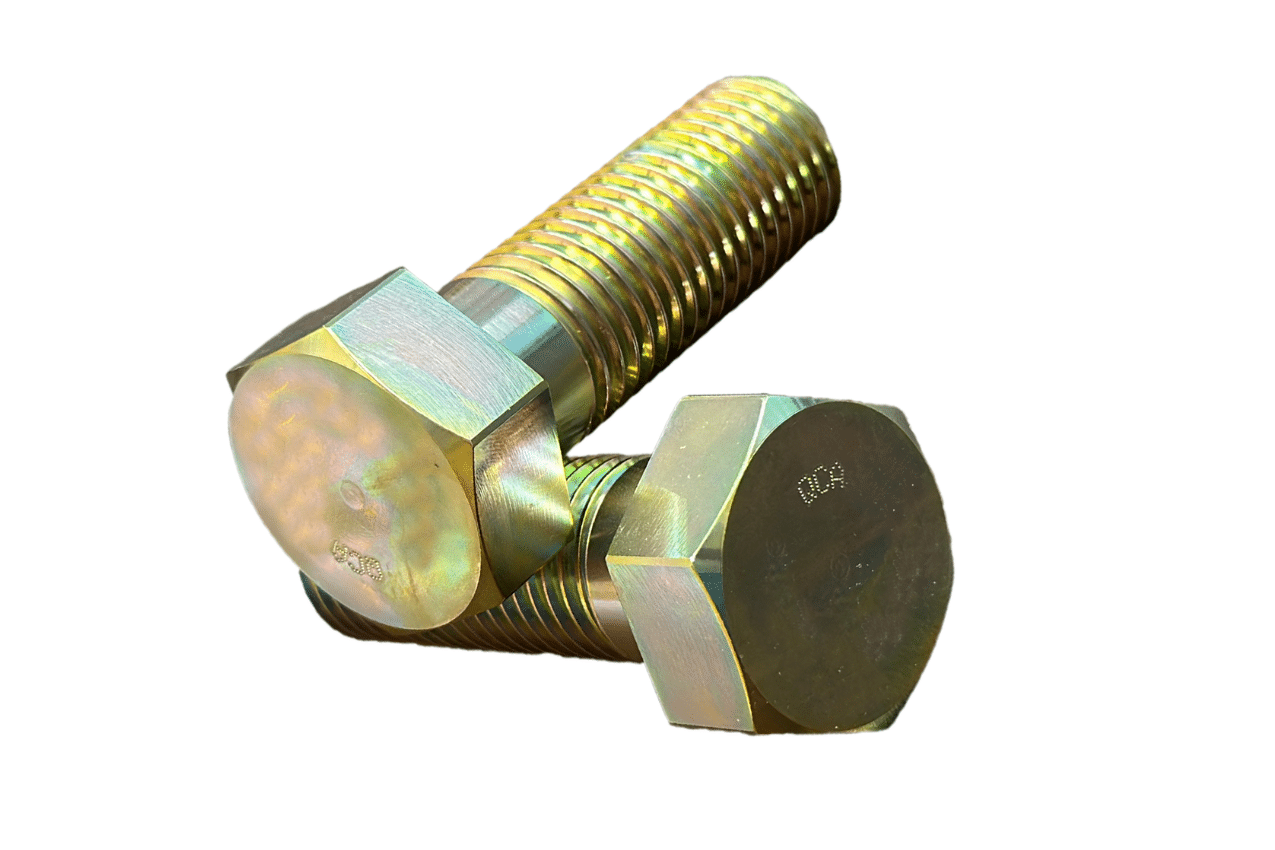

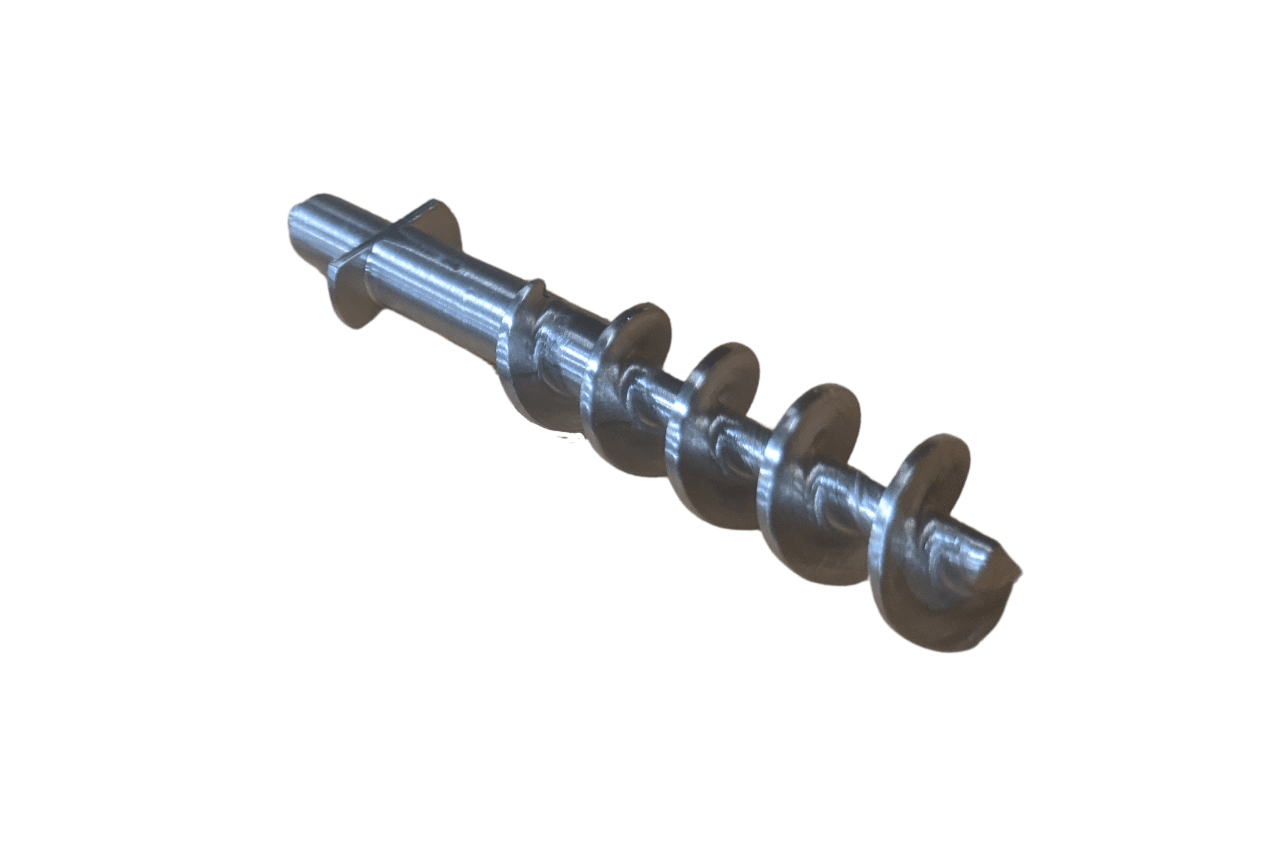

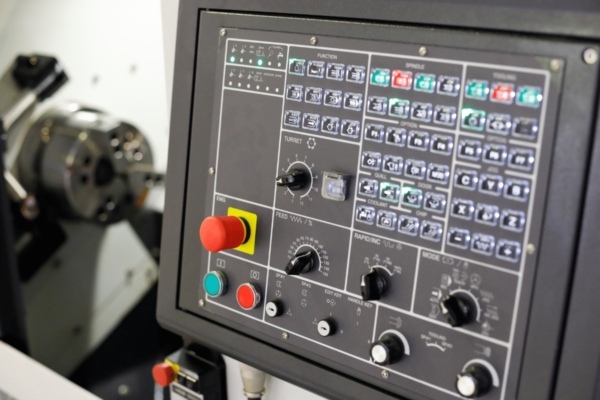

What is a CNC Turning Machine?

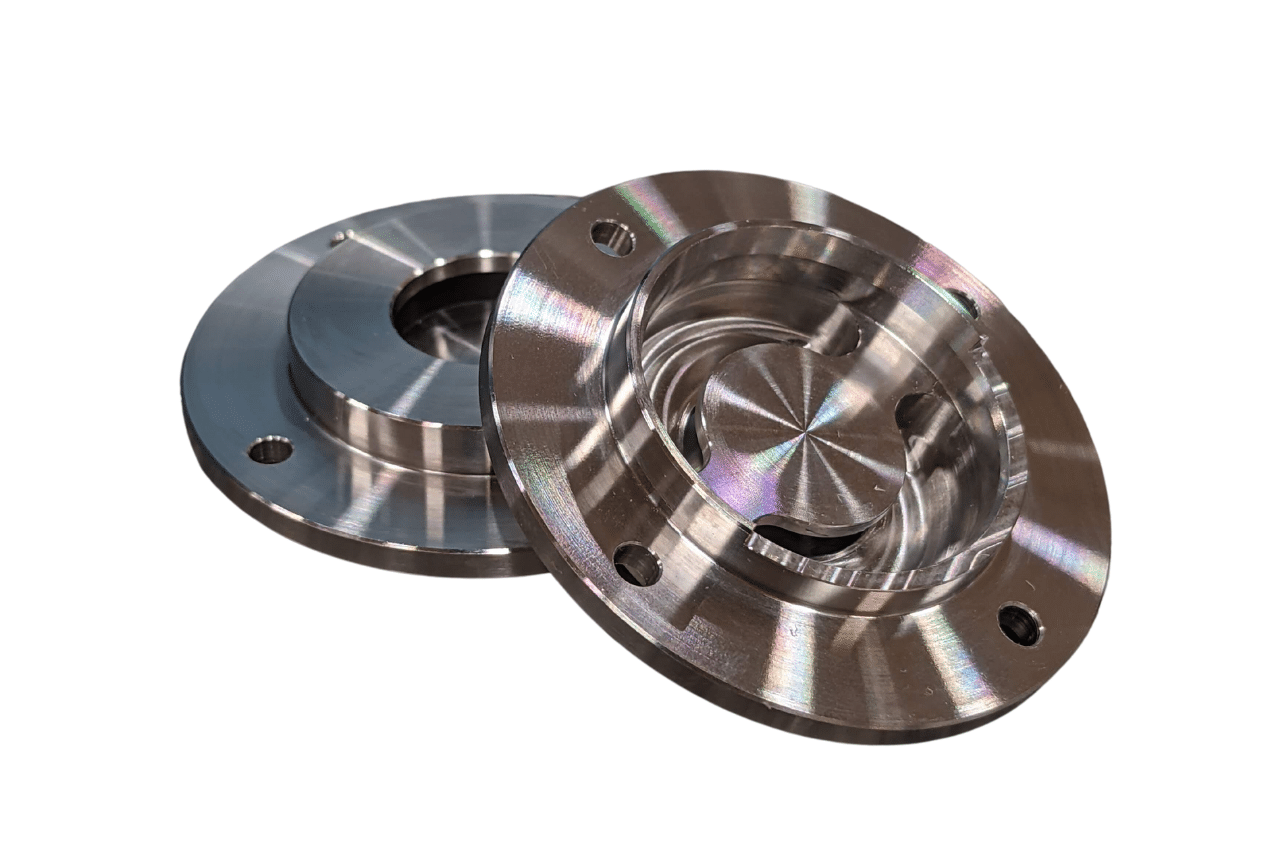

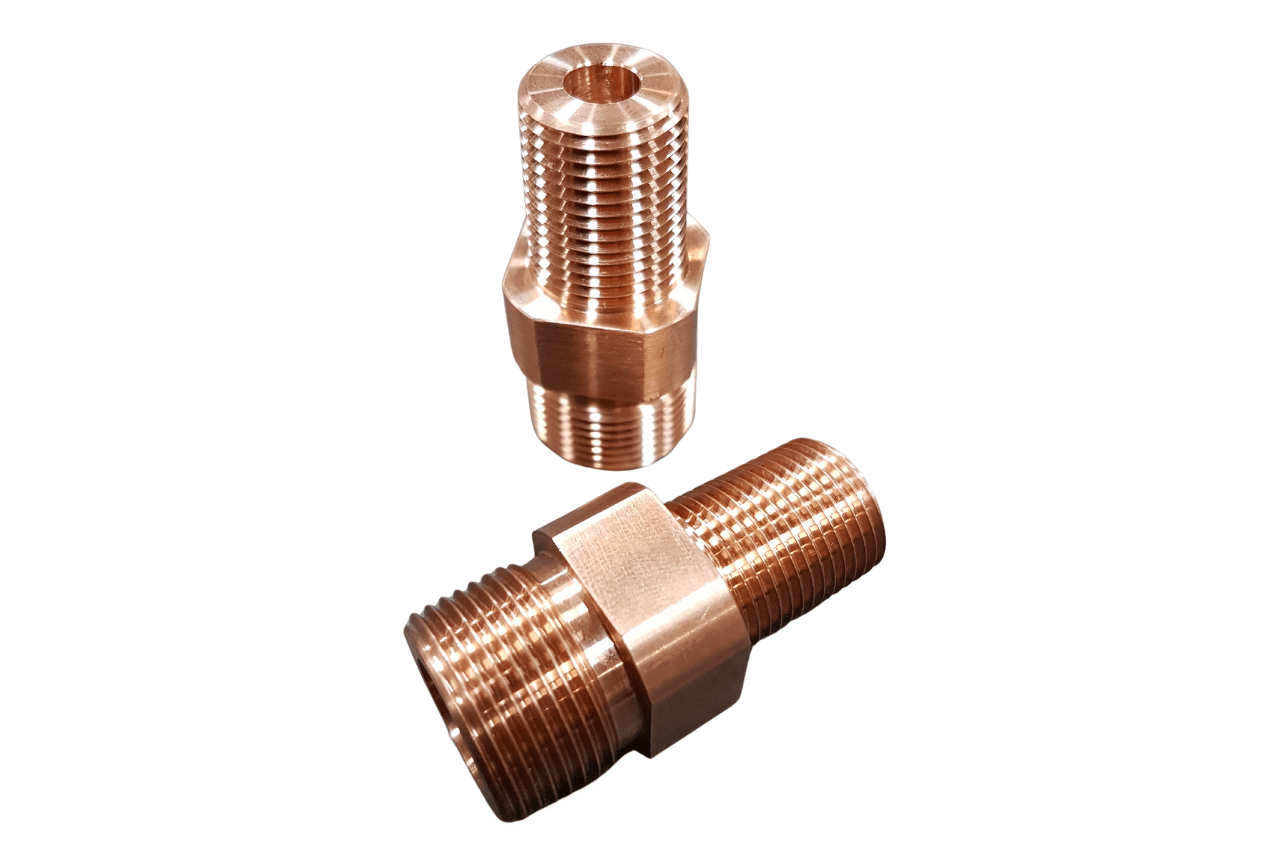

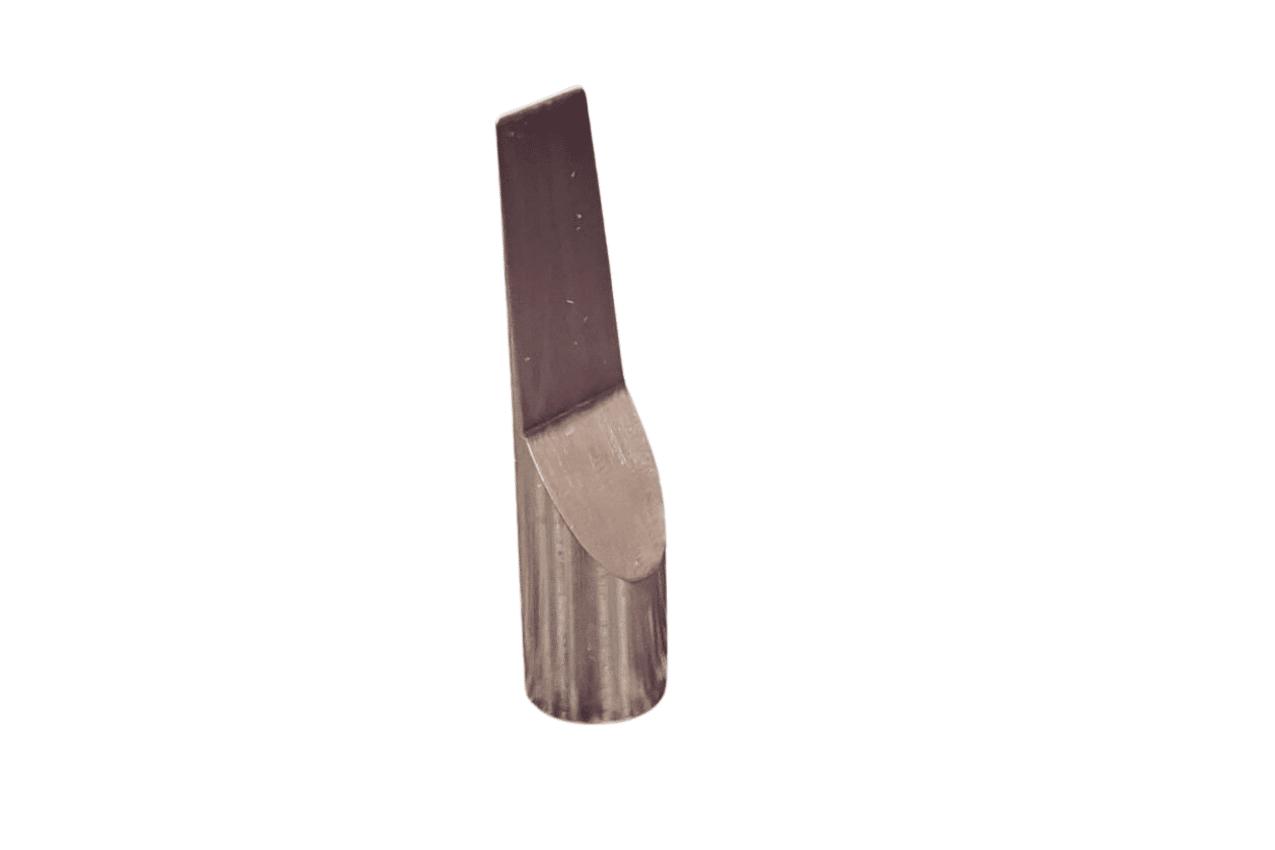

CNC turning machines utilize precise measurements and controlled movements to achieve accurate and meticulous cuts according to a programmed design. This ensures meticulous and accurate cuts in accordance with a programmed design. These machines excel at creating cylindrical shapes, such as shafts, bolts, and various similar components. Lathes are well-known for producing parts with a wide range of features, including stepped diameters, tapered sections, and threaded holes. The CNC turning process is renowned for exceptional accuracy and high-volume parts.

With their ability to produce consistent and reliable results, CNC turning machines play a vital role in the manufacturing industry, enabling the creation of complex and intricate components with the utmost precision. CNC turning machines are a cornerstone of modern manufacturing, delivering unmatched efficiency and excellence to various industries.

Rainhouse CNC Turning Capabilities

Our full CNC capabilities encompass up to 8-axis CNC turning machines.

Discover the technical details of our advanced CNC turning machines below.

Nakamura Tome WT-150ii

Max. Turning Diameter: 190mm

Max. Turning Length: 515mm

Left Spindle Speed: 4,500 RPM

Right Spindle Speed: 5,000 RPM

LNS Bar Feeder: 1200mm (L) | 65mm (D)

Puma 240M

Max. Turning Diameter: 350mm

Max. Turning Length: 439mm

Spindle Speed: 6,000 RPM